GENERAL : Cold water conveyance is the plumbing system. Texmo Plumbing System is best suitable for conveyance of water up to temperature level of 60° C. This system is accepted and recommended by WHO in water application.

RAW MATERIAL: Texmo Plumbing System comprises of pipes and fittings, made of PVC (Polyvinyl Chloride). The PVC compound contains specified quantity of chemical, stabilizer and other additives to facilitate extrusion.

PRODUCTION SPECIFICATION: The system is made as per ASTM (American Society for Testing Materials) Standards

| COLOUR | : | Blue and White with UV stabilization |

| MATERIAL | : | PVC Compound |

| SOLVENT CEMENT | : | Heavy Duty (Joints tested up to 35 kg/cm² pressure) |

| STANDARD LENGTH | : | Available in 3 meters and 6 meters, with threaded and plain ends. |

| PRESSURE CLASS | : | Pipes -SCH 40 and SCH 80, Fittings – SCH 80 |

| RANGE | : | Pipes and Fittings up to 4" Size |

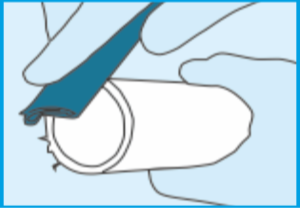

CUTTING: Cut pipe square to the required length by cutter, De-bur the cut end, if necessary. Pipes ends must be clean cut at right angles.

CLEANING: Prior to jointing, the pipe and fitting should be clean & dried properly.

SCRUBBING: Scrub the O.D. of the pipe and I.D. of fitting by using sand paper and clean it with cloth.

APPLICATION OF SOLVENT CEMENT: Apply gently and uniformly to the scrubbed I.D. of fitting and scrubbed O.D. of pipe with a suitable applicator. Again, apply another coating of cement uniformly to the O.D. of the pipe. Avoid applying excessive cement. Be sure to cover all jointing surface area of the pipe and fitting.

ASSEMBLY OF JOINT : Within 20 second of application of solvent cement to the pipe, insert the O.D. of pipe into the I.D. of the fitting and give a quarter turn for uniform distribution of solvent cement, ensure for proper setting of pipe and fitting. According to the alignment made, hold the joint tightly together for 15 secs to 3 min. or more, depending on the size. Remove excess cement from the O.D. of the pipe and the I.D. of the fitting.

CURING AND PRESSURE TESTING: Always allow minimum 12 hours curing period for each joint and the pressure test to be carried thereafter. For colder temperatures it is necessary to wait a longer period. Pressure test must be carried out before concealing.

WHITE PLAIN ENDED PIPES: These pipes are plain at both the ends can be joined with PVC fittings available in white colour. The joint formed between the pipe & fitting with the help of solvent cement is a permanent homogeneous joint.

– Light in weight, stronger and long lasting

– Excellent resistance to corrosion, chemicals, and abrasion.

– Most suitable for carrying drinking water (as recommended by WHO)

– UV stabilized

– Very smooth inner surface and hence no sediment deposition and no reduction in bore size

– Free from rusting and galvanic corrosion

UPVC (Unplasticized PVC) is suitable for cold water applications, while CPVC (Chlorinated PVC) is ideal for both hot and cold water due to its higher temperature resistance.

Yes, our pipes are made from non-toxic, lead-free polymers and are 100% safe for potable water usage.

Yes, our products are manufactured under strict quality standards and come with BIS (ISI) certifications, ensuring safety, strength, and reliability.

Our pipes have an average service life of 25–50 years depending on usage and environmental conditions.

We provide a full range of compatible fittings including elbows, tees, couplings, adaptors, valves, and solvent cements to ensure complete system solutions.

Our experts are here to help you! Get in touch with our team for quick assistance.

With our commitment to strength, precision, and innovation, we deliver piping solutions that not only support vital water flow but also empower communities, agriculture, and industries.