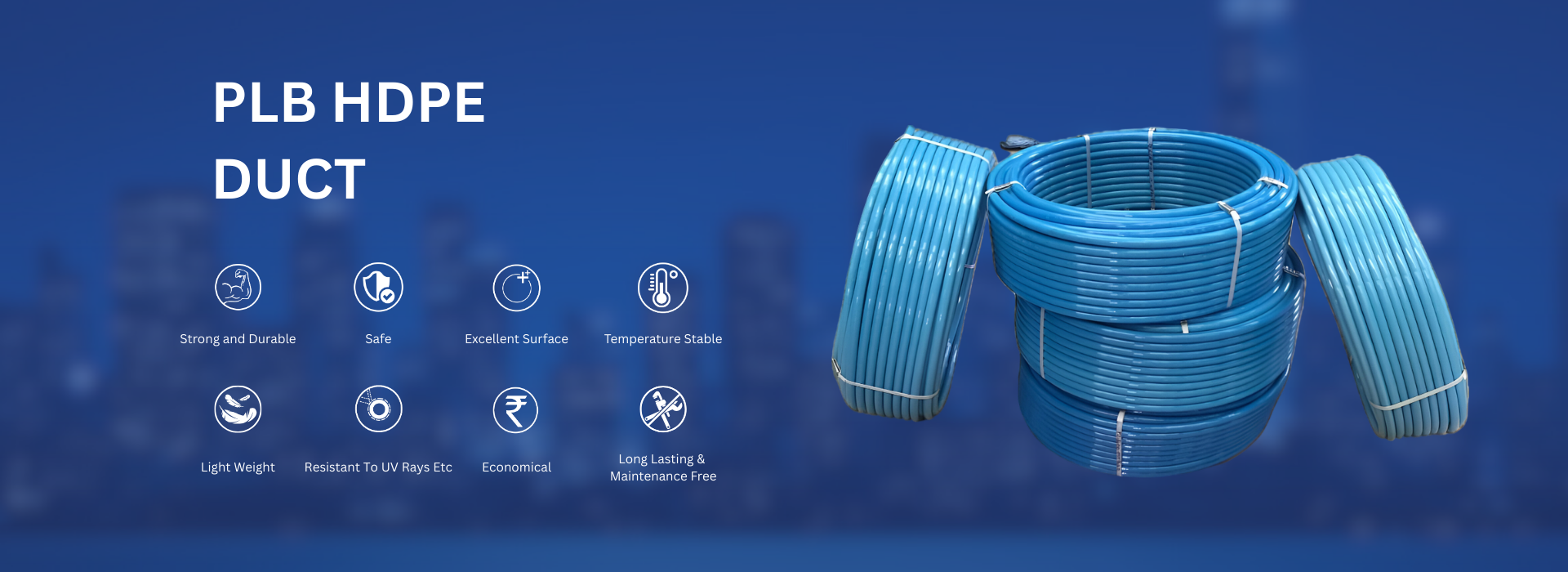

Manufactured as per norms of G.R. No. TEC/GR/TX/CDS-008/03 MAR-2011 & DR/MDS-01/04 FEB-2010. Used for housing fiber optic cable and metal cable, also used as basic backbone in communication.

TEXMO, as one of the largest processors of plastic materials in India, has introduced the following:

PVC, HDPE, Plain, Permanently Lubricated, Ribbed, Tracer & Large diameter ducts for safe placement of cables and future upgradation and replacement of damaged cables.

Industrial:TEXMO co-extruded permanently lubricated HDPE ducts are used for laying Optical Fibre Cable (OFC) as underground conduits.

| Size | Outer Diameter | Wall Thickness |

|---|---|---|

| 50 / 42mm | 50 mm | 4.0 mm ± 0.3 mm |

| 40 / 32mm | 40 mm | 3.5 mm ± 0.2 mm |

| 32 / 26mm | 32 mm | 3.0 mm ± 0.2 mm |

| 40 / 33mm | 40 mm | 2.5 mm ± 0.2 mm |

| 40 / 33mm | 40 mm | 3.0 mm ± 0.2 mm |

| 32 / 28mm | 32 mm | 2.0 mm ± 0.2 mm |

| 32 / 27mm | 32 mm | 2.5 mm ± 0.2 mm |

Manufactured as per ISO 4427. Supplied in blue/black color.

Product Range – Coils

Available in sizes from 16mm – 315mm

Pressure ratings in PE-63, PE-80 & PE-100 Grade

2.5 to 25kg/cm²

The raw material used is High Density Polyethylene (HDPE), conforming to:

IS : 7328-1992 or equivalent standard

IS : 2530 / ISO : 1183 & ISO : 1133 for testing

Properties:

Density: 0.940 to 0.958 gm/cc at 27°C

Melt Flow Index: 0.20 to 11 g/10 min at 190°C under 5 kg load.

| Strong And Durable | : | TEXMO MDPE Pipes are strong and durable. |

| Light Weight | : | Easy to handle, hence easy to transport and install. |

| Better Flow Characteristic | : | Smooth internal surface, rust proof, corrosion free. |

| Energy Saving | : | Less friction loss; lower power consumption. |

| Safe | : | Fire resistant and non-conductive. |

| Resistant To | : | 1)Rusting 2)Chemicals 3)Corrosion 4)Scale Formation |

With our commitment to strength, precision, and innovation, we deliver piping solutions that not only support vital water flow but also empower communities, agriculture, and industries.

Copyright © 2025 All Rights Reserved.