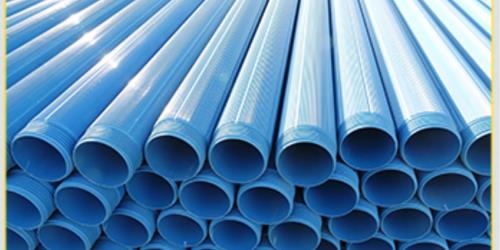

TEXMO Casing Pipes are manufactured under strict quality control with the latest technology as per IS-12818/2010 specifications, DIN: 4925 & ASTM-F480 Standards.

TEXMO Casing Pipes prove to be the most vital and long-lasting for a tube well when they are properly selected and installed as per the site conditions, thus making a tube well dependable for a longer period.

In the past, metal Casing of M.S. Material in plain as well as in screen were the first choice of the customer for their tube wells but over the period of time, due to deterioration of the metal of the screen pipe, due to rusting/corrosion and thereby formation of bacteria in the stagnant water and contamination of water source etc. Material for casing pipes was introduced to replace the metallic ones. It has not only replaced the metal pipes to PVC but also by way of the modification, researches developed will consequently more discharge of water in the bore well.

Thus TEXMO Casing Pipes are manufactured in different sizes and ranges to meet maximum site conditions and applications according to the need of the customer. These are manufactured as per the international standards after thorough checks by the quality control laboratory in our factory.

TEXMO Casing Pipes are best preferred for tube wells, domestic wells, irrigation wells, industrial wells, and mines.

TEXMO Casing Pipes have been preferred over other available resources due to varied salient features.

| APPLICATION | TEXMO uPVC Casing Pipes |

|---|---|

| Metal Casing and Screens are costly. | Installation is cost-effective with TEXMO casing and ribbed screens compared to conventional mild steel casing/screens. |

| Increased entrance resistance due to vertical slot opening. | Horizontal slot openings reduce entrance resistance and prevent collapse. |

| >50% of slot opening is obstructed by filtering media (Gravel Pack). | Rib on the screen keeps the filtering media 2mm away from the slot, increasing permeability. |

| Corrosive soil reduces life of tube wells. | TEXMO casing and screens made of inert uPVC; unaffected by corrosion. |

| Slot opening gets enlarged due to erosion. | uPVC slot openings are not subject to erosion. |

| Metal casings are cumbersome to install. | uPVC is 1/5th the weight of steel making it easier to handle/install. |

| Metal casing needs special tools and sets. | No special equipment needed due to spigot ends and trapezoidal threads. |

| Various screens needed for aquifer sieve analysis. | Available in slot widths from 0.2mm to 3mm to suit aquifer needs. |

| Types | Description | Sizes | Depth in Mtr |

|---|---|---|---|

| CS | Shallow Well Casing | 150mm to 400mm | Up to 80 |

| CM | Medium Well Casing | 35mm to 400mm | 80 to 250 |

| CD | Deep Well Casing | 100mm to 400mm | 250 to 450 |

| RMS | Ribs Medium Well Screen | 35mm to 400mm | Not Applicable |

| RDS | Ribs Deep Well Screen | 100mm to 400mm | Not Applicable |

| PMS | Plain Medium Well Screen | 200mm to 400mm | Not Applicable |

| PMS | Plain Deep Well Screen | 200mm to 400mm | Not Applicable |

With our commitment to strength, precision, and innovation, we deliver piping solutions that not only support vital water flow but also empower communities, agriculture, and industries.

Copyright © 2025 All Rights Reserved.